HDPE Epoxy Mold Release Spray

Share

In this blog post, we'll delve into what epoxy release spray is, how it works, and why it's a valuable addition to any woodworker's toolkit.

Epoxy release spray, also known as mold release spray, is a specialized product used in woodworking to prevent epoxy resin from sticking to molds, forms, or surfaces during the curing process. It creates a barrier between the epoxy and the substrate, allowing for easy release once the epoxy has fully set. This can be particularly useful when working on intricate epoxy resin projects, such as river tables, coasters, or decorative items.

How Does Epoxy Release Spray Work?

The effectiveness of epoxy release spray lies in its formulation, which typically includes a blend of lubricants, surfactants, and release agents. When applied to a surface, the spray forms a thin, non-stick layer that prevents the epoxy from bonding permanently. This allows the cured epoxy to be removed effortlessly, leaving behind a clean and smooth finish.

To use epoxy release spray, simply shake the can well and apply an even coat to the surface or mold before pouring the epoxy resin. It's essential to follow the manufacturer's instructions regarding drying times and application methods for optimal results.

Benefits of Using Epoxy Release Spray in Woodworking:

-

Easy Release: The primary advantage of using epoxy release spray is that it facilitates easy release of cured epoxy from molds or surfaces. This is crucial for maintaining the integrity of the epoxy piece and avoiding damage during demolding.

-

Cleaner Finishes: By preventing epoxy from sticking to the mold, release spray helps achieve cleaner and smoother finishes. This is especially important for projects where surface quality is paramount, such as tabletops or artistic resin pieces.

-

Time-Saving: Without the need to struggle with stubbornly stuck epoxy, woodworkers can save time during the demolding process. This allows for more efficient workflow and faster turnaround on projects.

-

Versatility: Epoxy release spray can be used with various types of molds, including silicone, plastic, or metal. It's compatible with most epoxy resins, making it a versatile solution for different woodworking applications.

-

Reduced Waste: Improved release properties mean less waste due to damaged or unusable epoxy pieces during demolding. This contributes to cost savings and a more sustainable woodworking practice.

Tips for Using Epoxy Release Spray Effectively:

-

Apply Evenly: Ensure thorough and even coverage of the spray on the mold or surface to prevent areas where epoxy may adhere.

-

Follow Drying Times: Allow the release spray to dry completely according to the manufacturer's instructions before pouring epoxy resin.

-

Clean Molds Regularly: Clean molds between uses to remove any residue or buildup that could affect the release properties of the spray.

-

Store Properly: Store epoxy release spray in a cool, dry place away from direct sunlight or heat sources to maintain its effectiveness.

In conclusion, epoxy release spray is a valuable tool for woodworkers working with epoxy resin. Its ability to facilitate easy release, improve surface quality, and save time makes it a must-have product in any woodworking workshop. By incorporating epoxy release spray into your projects, you can achieve professional results and enhance your overall woodworking experience.

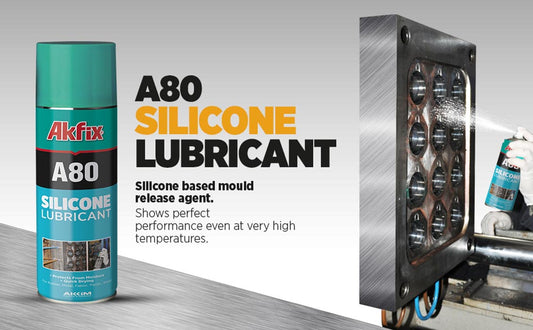

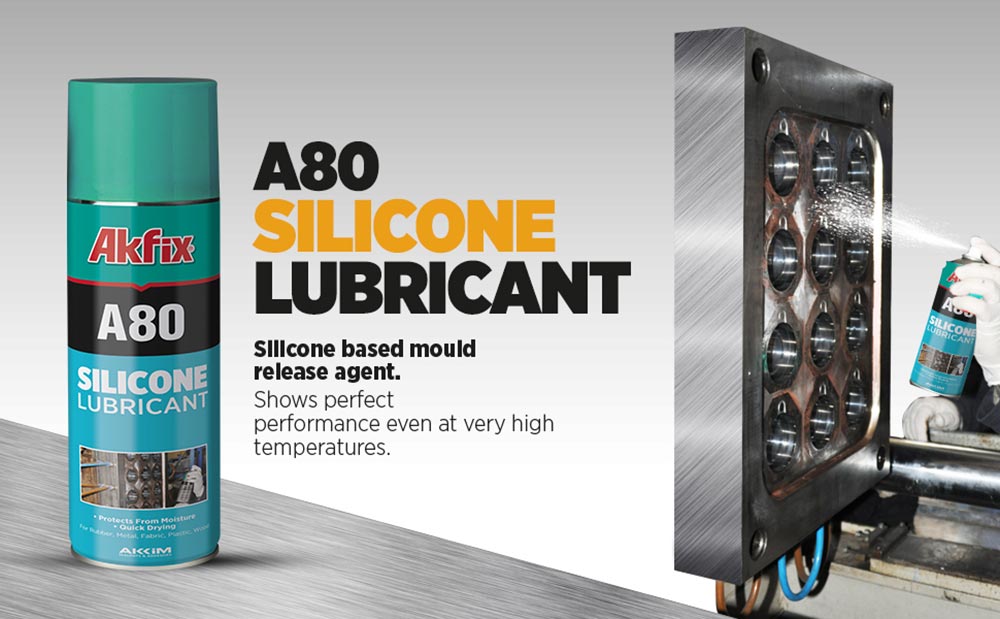

Looking for a great release spray? Grab a can of our Akfix AK-A80 Silicone Lubricant Spray