5 Tips on how to Avoid Microbubbles with Nerpa Polymers Epoxy

Share

One of the common issues customers might experience with their projects is tiny microbubbles that are present in their epoxy after it is cured. This often happens with products that are not optimized for air release.

Here are 5 things you should look at before your next pour...

Use high quality, low viscosity resin.

- A simple and easy solution can help improve your resin projects' quality. Low viscosity casting epoxy resin features properties and flow to overcome the slowing down movement and stall of microbubbles in thicker resins. Nerpa Polymers Casting Epoxy has one of the lowest viscosities on the market (Nerpa's Casting Epoxy 215-250 Centipoise while the industry standard for deep pour resins is 400-600 Centipoise. The higher the Centipoise number, the thicker the resin).

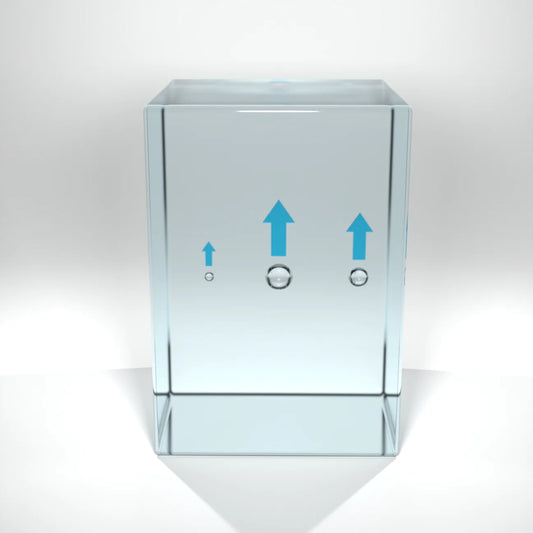

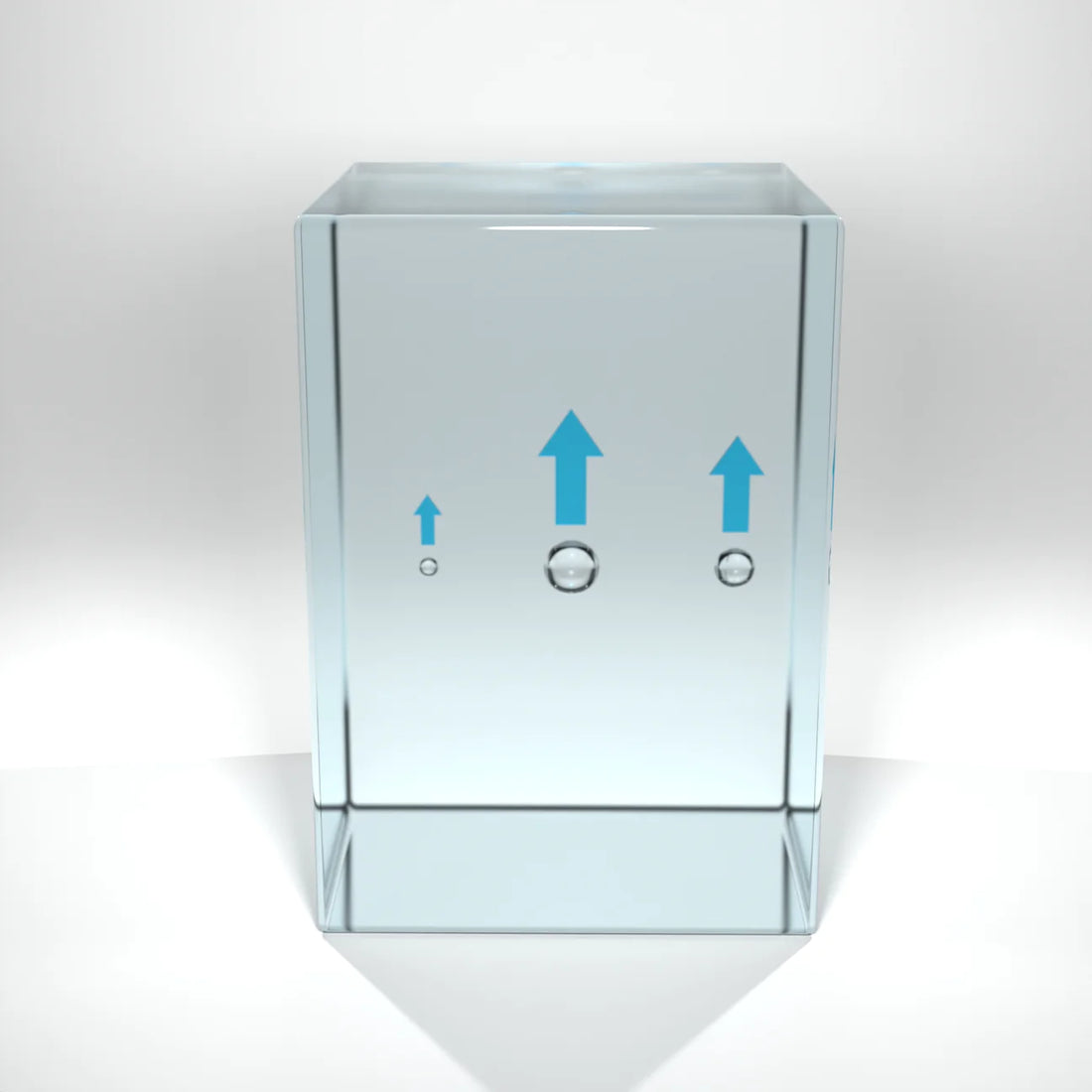

Start using vacuum degassing chamber

- Another good way to improve the visual clarity of the casting is to use degassing chamber prior to pour. Negative pressure in the chamber will force bubbles to rise to the surface faster and and pop. On the other hand, vacuum degassing chambers are usually too small to accommodate large quantities of resin and using them might require extra time and effort.

Seal pores in the wood / warm the wood up

- If you are going to use wood with epoxy, it would be a good idea to seal it or to warm it up before pouring the epoxy. These two effective tricks will help stop the formation of the small bubbles from the pores and wood cracks. You can read more about these techniques in our "How to remove air bubbles from your epoxy" blog post.

What you should definitely avoid doing:

Increasing temperature in your shop

- Although higher temperature lowers the viscosity of the epoxy resin, we do not recommend working in the warmer conditions or preheating your epoxy resin for deep pour projects as it might enter the exothermic runaway (warm up quickly to high temperatures).

Thinning your epoxy with solvents or alcohols

- Diluting or thinning resin with solvents and/or alcohols is detrimental to the structural properties of epoxy, especially in deep pour applications.